What Are Battery Coatings and Why Do They Matter?

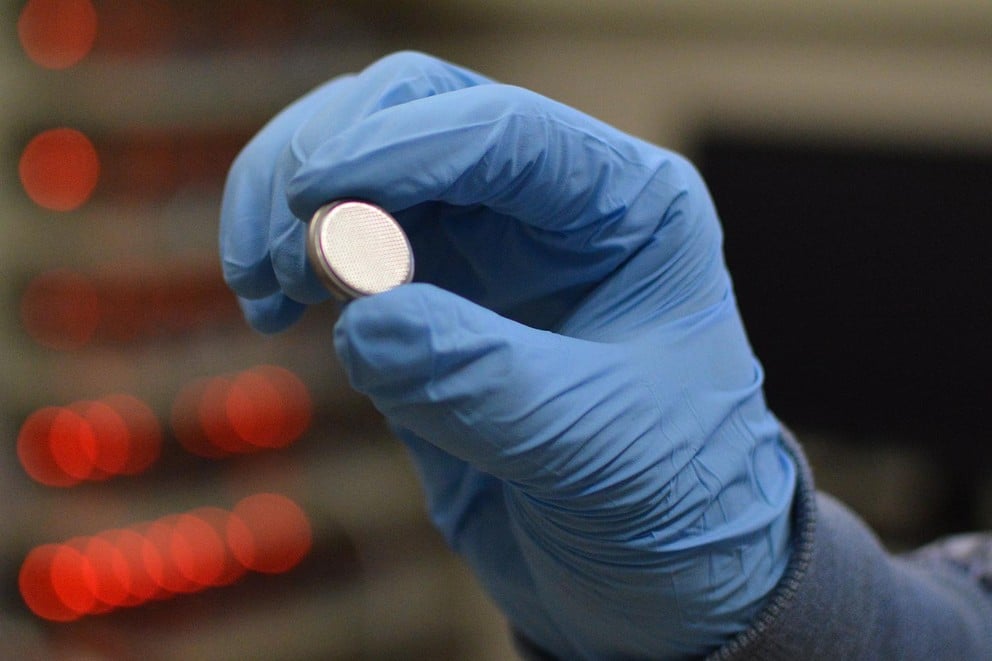

Battery coatings are specialized surface treatments applied to battery electrodes, separators, and current collectors. They serve multiple purposes:

- Prevent side reactions between electrode materials and electrolytes

- Enhance thermal stability and reduce overheating risks

- Improve charge/discharge rates and overall energy efficiency

- Extend cycle life by reducing material degradation

- Enable new chemistries like lithium-sulfur or solid-state batteries

Coatings can be made from ceramic, polymer, metal oxide, or carbon-based materials, and they’re often applied through atomic layer deposition (ALD), chemical vapor deposition (CVD), or sol-gel techniques.

Driving Forces Behind Market Demand

- Booming Electric Vehicle Industry

Electric vehicles rely on safe, long-lasting, high-energy-density batteries. Battery coatings help stabilize battery chemistry, reduce thermal runaway risk, and enable faster charging, which is key to improving EV performance.

- Rise of Solid-State Batteries

Next-generation solid-state batteries use coatings to create stable interfaces between solid electrolytes and electrodes. Without coatings, these materials can degrade or short-circuit over time.

- Need for Longer Battery Life in Electronics

In consumer electronics, users expect longer battery life and faster charging. Coatings improve efficiency and reduce internal resistance, helping devices perform better over more charge cycles.

- Grid-Scale Energy Storage

With the global shift to renewables, battery storage is needed to stabilize the power supply. Battery coatings enhance battery life and safety for stationary energy storage systems (ESS).

Regional Market Insights

- Asia-Pacific leads the global battery coating market, with countries like China, South Korea, and Japan at the forefront of battery manufacturing and electric mobility adoption.

- North America is seeing growing demand due to expansion in EV production, particularly in the U.S., along with federal incentives for clean energy.

- Europe is investing heavily in battery gigafactories and green mobility, positioning itself as a rising hub for advanced battery research and innovation.

Key Materials and Technologies

The battery coating market includes several material categories and technology platforms:

- Ceramic Coatings – Provide thermal stability and prevent dendrite growth

- Polymer Coatings – Improve flexibility and protect against moisture

- Aluminum Oxide & Metal Oxides – Used in ALD to prevent degradation

- Carbon Coatings – Enhance conductivity and reduce resistance

- Atomic Layer Deposition (ALD) – Precise, ultra-thin coating method ideal for solid-state batteries

- Chemical Vapor Deposition (CVD) – High-purity coatings used in advanced applications

- Slurry Coating & Dip Coating – Used for commercial lithium-ion battery electrodes

Leading Players in the Battery Coating Market

Several global companies are actively developing battery coating solutions:

- NEI Corporation – Known for nanocoatings and solid electrolyte interfaces

- Arkema Group – Offers polymer coatings for battery separators and electrodes

- Solvay – Produces high-performance materials for lithium-ion batteries

- SK Innovation – Focuses on coating technologies for EV batteries

- 3M – Provides fluorinated coatings and ceramic materials

These players invest in R&D, joint ventures, and scale-up efforts to meet market demand.

The Road Ahead

The future of the battery coating market is closely tied to the evolution of battery technology itself. As lithium-ion reaches its performance limits, coatings will become even more critical in enabling:

- Solid-state batteries

- Lithium-metal and silicon anode batteries

- Cobalt-free or high-nickel cathode chemistries

- Recyclable and sustainable battery designs

Additionally, new regulations on battery safety, lifespan, and recycling will drive further innovation in coating materials and application techniques.

Final Thoughts

The global battery coating market is more than just a supporting player; it’s becoming a key enabler of the energy transition. Whether powering an electric car, stabilizing a solar grid, or fueling the next smartphone, coatings ensure that batteries are safer, longer-lasting, and more efficient.

With demand set to rise sharply through 2030 and beyond, battery coatings will play a pivotal role in shaping the future of energy storage one layer at a time.

Learn More and Take Action:

Consider becoming a member of the BCC Research Library and gain access to our full catalog of market research reports in your industry. Not seeing what you are looking for? We offer custom solutions too, including our new product line: Custom Intelligence Services.

Contact us today to find out more.